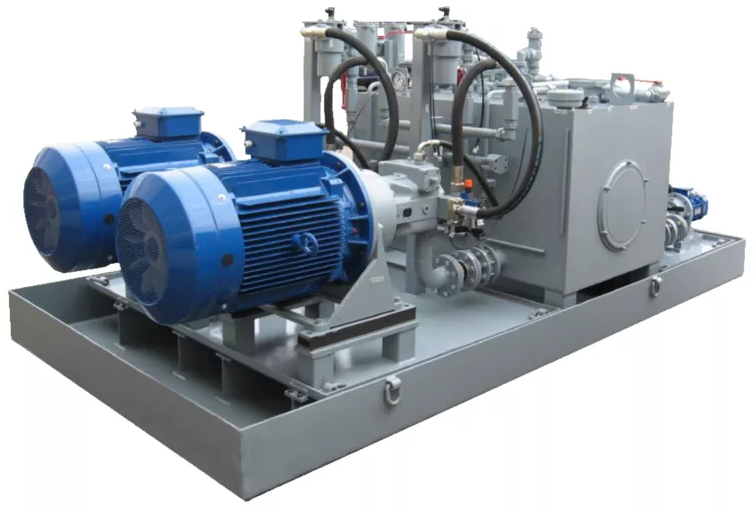

Power Units

Hydraulic stations: up to 15,000 dm³ tanks (Al, steel, stainless), supports mineral/gear/flame-retardant liquids. Standard cutting ring, welded cone, or flared fittings. Drive power up to 110 KW/assembly. Optional noise encapsulation. Complete 'single-source' systems provided, including motors, cylinders, controls/wiring, and multilingual documentation.

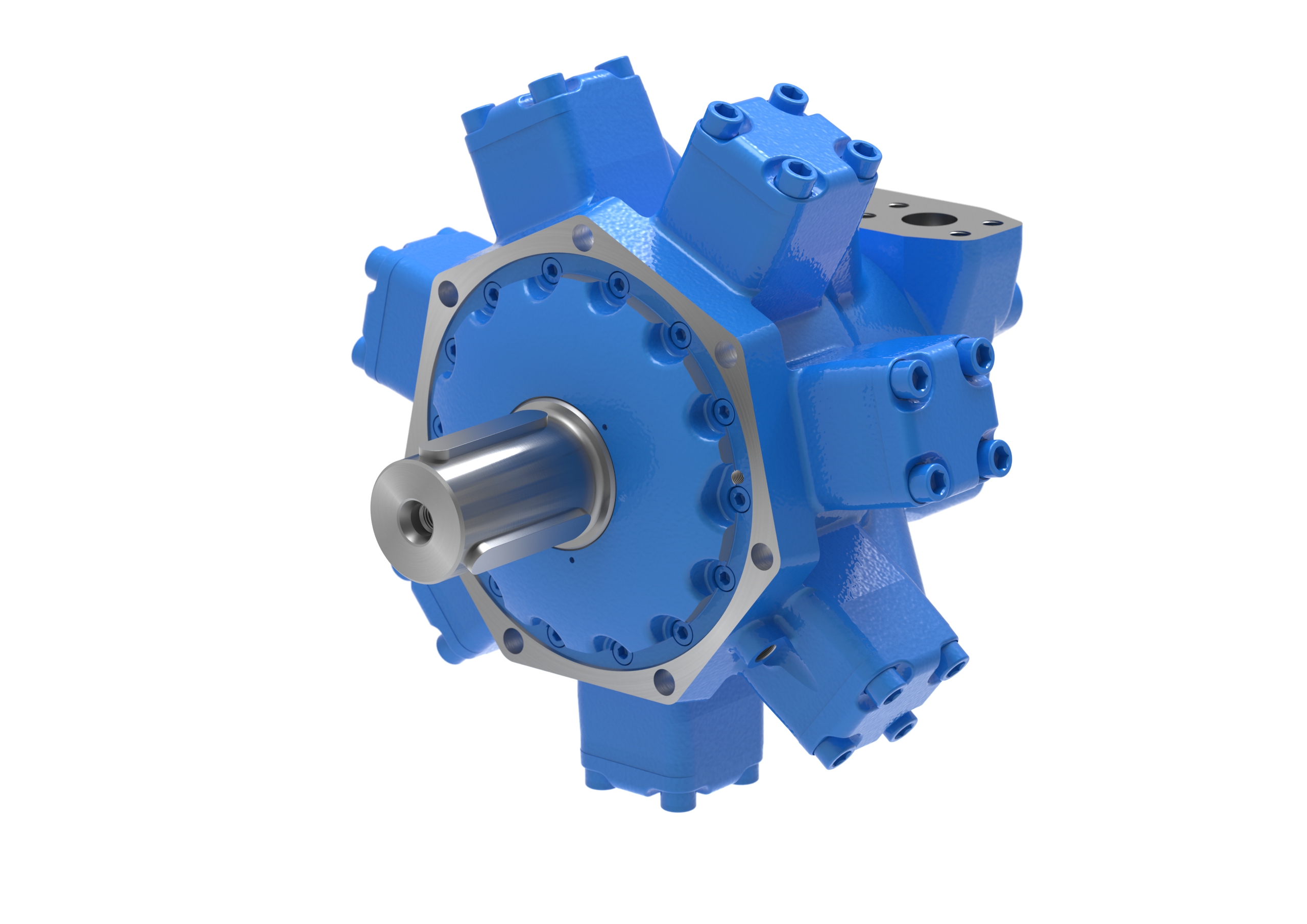

Hydraulic Motors

Axial Piston Motors: High power density, wide speed range, excellent low-speed synchronization. Radial Piston Motors: Compact, exceptionally long service life, very uniform operation, ideal for low-speed/control applications. RMX Series (Radial): Suited for high continuous power & harsh conditions. Extended service life (via robust design), high thermal/load capacity, high efficiency. Special versions for flame-retardant/biodegradable fluids.

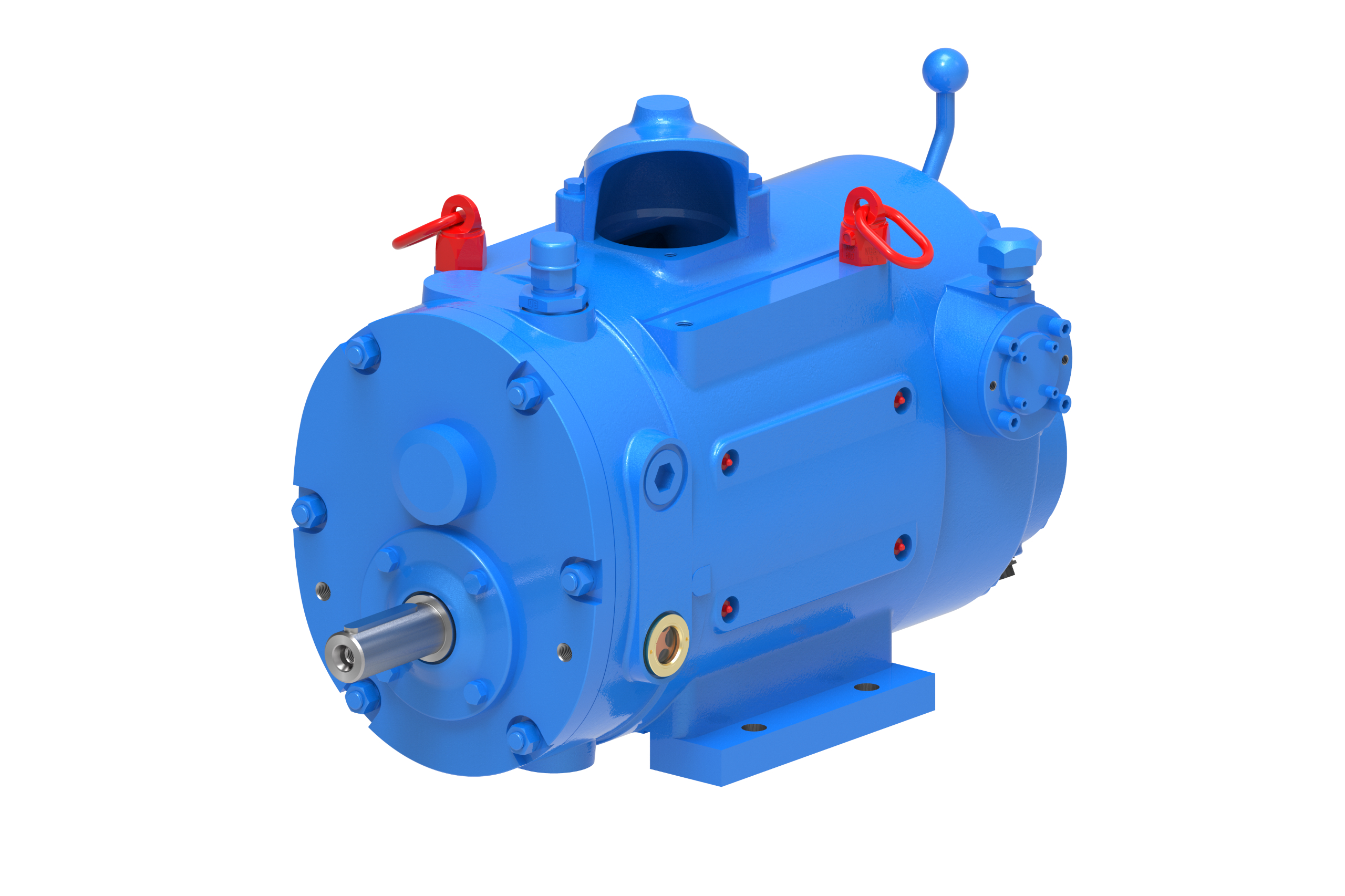

Pneumatic Motors

Düsterloh pneumatic motors are known for their highly robust construction and design. This makes them ideal for continuous duty and challenging operating conditions. Pneumatic technology offers inherent advantages over alternative energy transmission methods. Compressed air, nitrogen and other suitable gases can be stored easily and transported efficiently over long distances with minimal pressure loss. This makes pneumatic motors particularly well-suited for use as emergency drives, which are often found in metallurgy and rolling mill equipment.

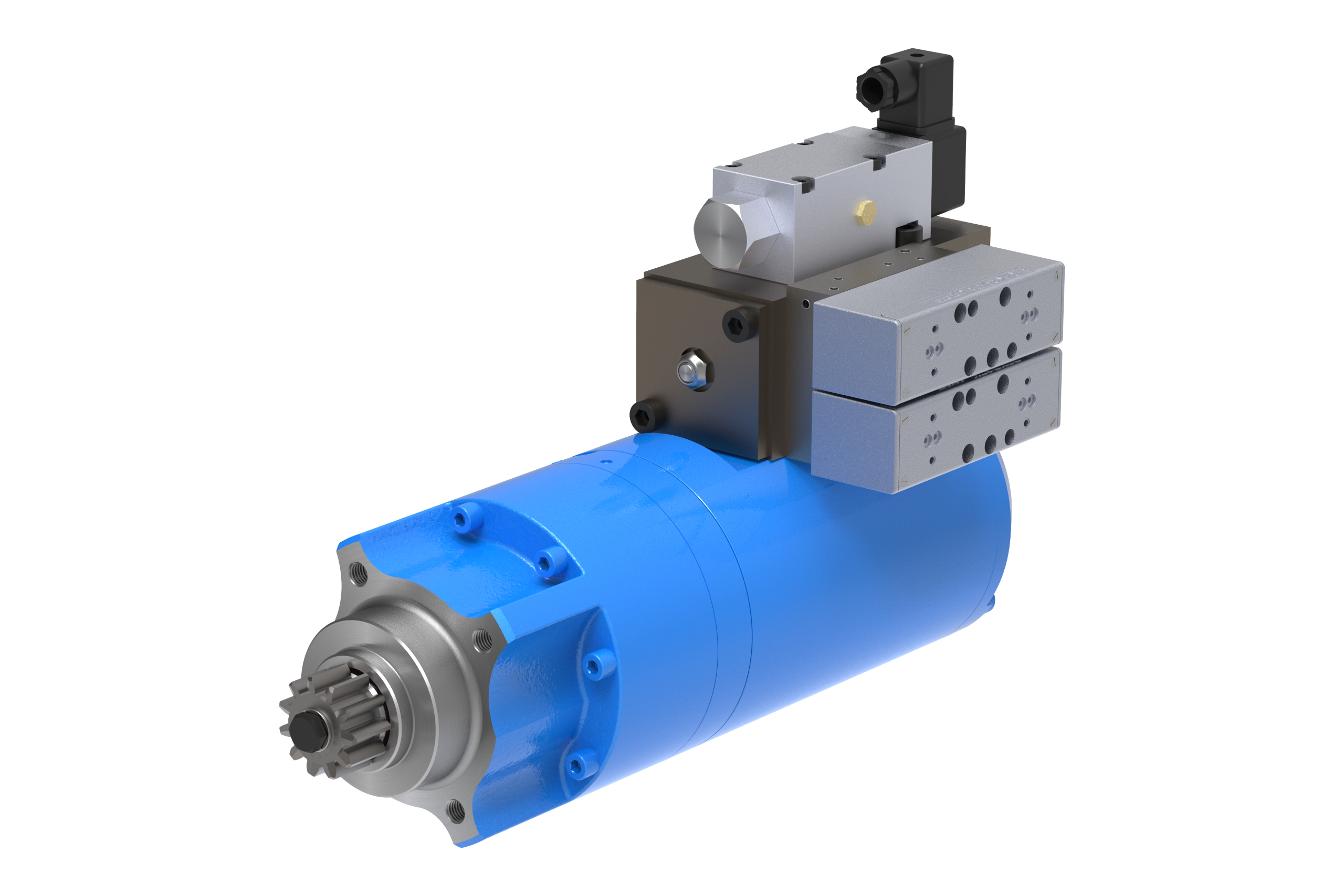

Pneumatic Starters

Düsterloh pneumatic starters are designed for starting diesel engines and turbines. 1 Operating on air or gas, they are maintenance-free, explosion-proof, and independent of electrical storage. Their design, featuring a gear motor that provides high break-loose torque, makes them particularly effective for diesel engines. Standard series deliver up to 510 Nm torque at the starter pinion (15 bar). For higher power requirements, two starters can operate in parallel, incorporating a safety circuit that ensures full pinion engagement before engine start.